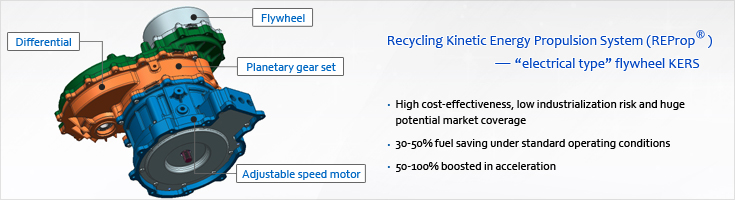

¡°Electrical type¡± flywheel KERS-Recycling Kinetic Energy Propulsion System (REProp®) developed by HAIKE is a cutting edge technology in power train of clean energy vehicle. The vehicle¡¯s kinetic energy is recovered when under braking and stored in flywheel in form of mechanical energy. When vehicle is under acceleration, the energy stored in flywheel is released as power assistance to enhance vehicle power performance and reduce fuel consumption.

¡°Electrical type¡± flywheel KERS by HAIKE utilizes innovative method of integrating flywheel and control motor into vehicle power train via a planetary gear set and implements electrical continuously variable transmission by an innovative system control strategy. The power is transmitted in or out of flywheel at 2 or 3 times of bigger scale than the specific power rated in control motor and achieves more than 50% of efficiency in power transmission between flywheel and vehicle drive train. In contrast with conventional hybrid technology, it has advantages such as significant reduction in fuel consumption, extensive application and low cost, etc. The performance is enhanced as 30-50% reduction in fuel consumption and 50-100% boosted in acceleration for the vehicle equipped with ¡°electrical type¡± flywheel KERS.

The photos showed above is a album of the products "electrical type" flywheel KERS by HAIKE and it shall be enlarged by clicking.

Table: Specifications

|

Type of flywheel KERS |

¡°Electrical type¡± |

|

The transit route of energy in and out of flywheel |

Mechanical |

|

Efficiency of braking energy recovery (%) |

70 |

|

System efficiency (%) |

>85 |

|

System weight (kg) |

50 |

|

The dependence upon motor and controller |

Low |

|

Flywheel kinetic energy maintenance |

Supplementing energy into flywheel and reduce the maximum speed requested by flywheel control motor |

|

Flywheel operating condition |

Normal atmospheric pressure |

|

Max. rotating speed of flywheel (rpm) |

25,000 |

|

Material of flywheel |

Steel |

|

Torque transmit controlling |

Linear vector control, high capacity of torque transmit |

|

Bearing |

Made of steel |

|

Request upon flywheel containment |

Relatively lower |

|

Power connecting |

Multi-models of power connecting |

The table below is a comparison among three technical routes of flywheel KERS: ¡°electrical type¡± by HAIKE, ¡°energy storage type¡± by Williams Hybrid Power¡± and ¡°mechanical type¡± by Flybrid.

|

Developer |

Flybrid |

Williams Hybrid power |

HAIKE |

|

The type of flywheel KERS |

Mechanical |

Energy storage |

Electrical |

|

The transit route of energy in and out of flywheel |

CVT |

Electrical driving system |

Major energy flow transmitted by mechanical coupling, small portion by electrical power train via a smaller double MGU. |

|

The efficiency of energy transformation |

High efficiency by mechanical coupling |

Relatively lower due to multiple energy transformation (electrical-kinetic-chemical) |

Remain the advantage of high efficiency as in ¡°mechanical type¡± |

|

The dependence on motor and inverter |

Low |

High dependence on big capacity of electrical power train |

Much lower in contrast with ¡°Energy Storage Type¡± |

|

Flywheel operating condition |

In strick vacuum |

In strick vacuum |

Normal atmospheric pressure |

|

The max. flywheel rotating speed (rpm) |

64,500 |

40,000-45,000 |

25,000 |

|

The material of flywheel |

The flywheel rim is made of carbon fiber composite |

Applying magnetic loading composite (MLC) technology |

Metal |

|

Torque transmit control |

Nonlinear control, lower capacity of torque transited |

Via electrical power train |

Vector control, big capacity of torque transit |

|

Bearing |

Ceramic ball bearing |

Ceramic ball bearing |

Conventional steel bearing |

|

Flywheel containment |

High dependence |

Relatively high dependence |

Relatively low dependence |

|

System integration demanded |

Relatively high |

low |

Relatively low and implemented by software |

|

The power connecting way |

Paralleling connecting only |

Connecting in series only |

Multi-models of power connecting |